Cooler Infeed/Outfeed Remove & Replace – Power Generation

Scope Of Work:

Replace an infeed water box & elbow and outfeed water box and spool section from coolers at the PSEG Hudson Generating Station fossil fuel plant. The equipment was located in a basement area with tight clearances and low headroom. Our approach consisted of using two (2) low-headroom lift trucks in the basement area. The lift trucks were lowered into the basement through a material handling vertical opening where the overhead (OH) crane lacked sufficient capacity for the load. We made sure to implement our safety protocols to do the job right the first time.

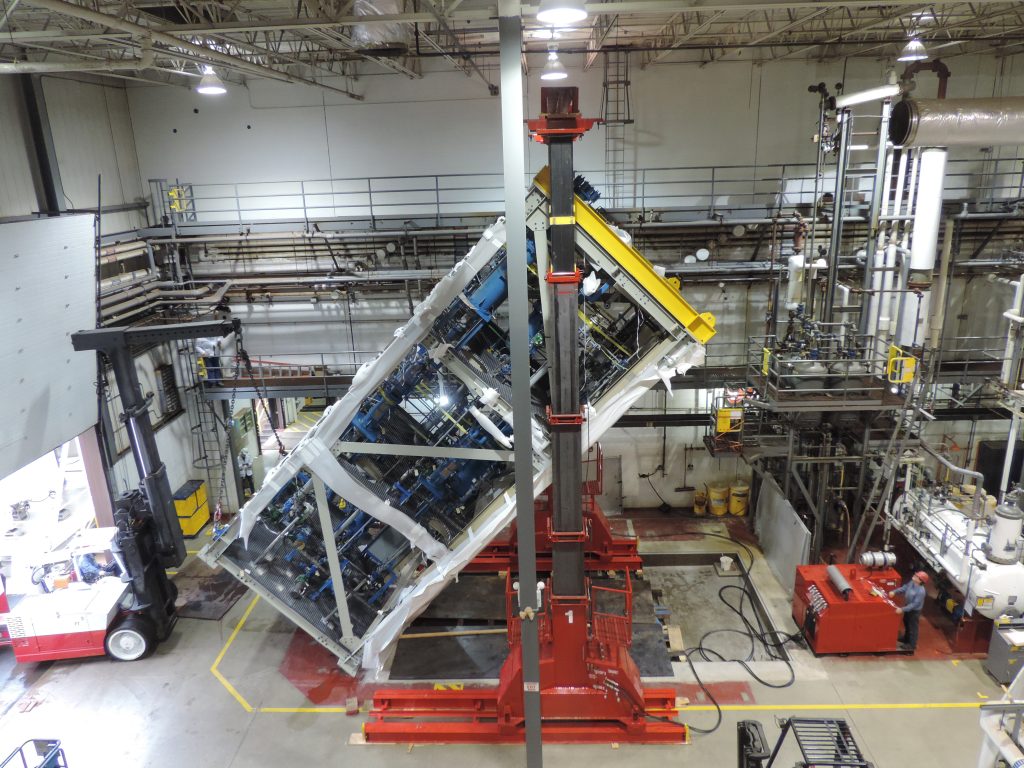

Lowering 14,500 lb. low-headroom lift truck into basement area using a Versa-Lift™ Model 25/35 with boom hoist attachment. Note the Versa-Lift™ is on a cribbed and plated platform level with the floor, enabling the lift to access the opening.

We used a Model 25/35 Versa-Lift ™ with a boom and cable hoist attachment to lower the lift truck in the basement. To get close enough to the opening with our Versa-Lift™, we had to crib and plate a level platform over a recessed floor area. Our approach shortened the outage period from what was originally planned and minimized the additional piping and equipment that would otherwise have been needed to be removed and reinstalled to accommodate the water box replacements.

Unique Challenges:

Because the water boxes were connected to intakes and discharges on the Hackensack River, daily tides affected specific tasks in the removal and replacement of the water boxes and large bore piping. The sequencing of the project and specific tasks were coordinated with the tide schedule.